3D Printing Could Make Inventory, Returns Less Complex for Retailers

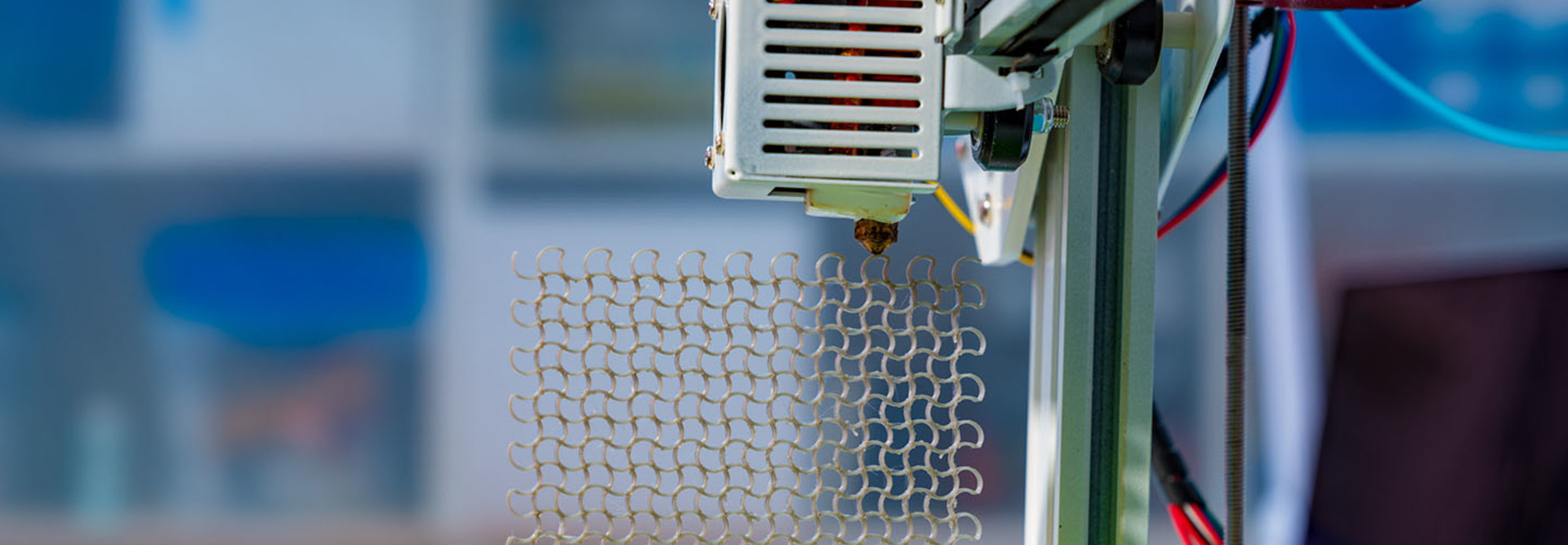

Clothes shopping can be frustrating for people with uncommon shapes or understocked sizes; you rarely find what you want, and when you do, it rarely fits 100 percent comfortably. 3D printing may change the nature of the retail experience for that group — and for retailers who can’t always predict what their customers want.

“A lot of people are passionate about this tech,” says Fatma Baytar, an assistant professor in Cornell University’s department of fiber science and apparel design. “People are trying different ways to make it user friendly. It’s a neat idea.”

Some companies are already experimenting with 3D printing in the manufacturing process. Adidas began making customizable, 3D-printed midsoles for its running shoes in 2015 and is now using an advanced version of 3D printing that creates a finished product with more consistent quality and durability.

But in that context, 3D printing simply changes how work is done in the factory, not the customer’s experience in the store. So adidas also tested a pop-up store in Germany in 2017 where shoppers could get customized knit sweaters made by a knitting machine after a body scan.

“If we can give the consumer what they want, where they want it, when they want it, we can decrease risk. At the moment, we are guessing what might be popular,” adidas’ head of Global Brands Eric Liedtke said to investors at the time, according to Reuters.

MORE FROM BIZTECH: Check out how retailers are adjusting to a tech-savvy world.

3D Printing Can Reduce Returns

Retailers would like to have a better idea of what the customer wants, especially as the number of returns balloons. Many shoppers deliberately order more than one of an item online so that they can test different sizes or colors, and return what doesn’t suit them; more than 40 percent of retailers have seen an increase in these “intentional returns,” says a report by Brightpearl.

Amazon, one of the largest clothing retailers in the world, is trying to get around this practice with its 3D body scanning unit, which is creating statistical models of bodies to assist in developing as yet unspecified commercial applications, reports The Wall Street Journal: “Technology to model a human body and how clothing will look on it has a wide range of applications, from being able to prevent returns of ill-fitting garments to on-demand printing and production.”

The technology can also cut down on excess inventory. OnPoint Manufacturing will custom make even a single article of clothing for a designer, “allowing shoppers to obtain apparel in fits and size combinations that even wider rack selections don’t provide,” reports Retail Dive. This eliminates the need for warehousing, minimum runs and inventory for small clothing-design firms, according to OnPoint’s website. The company recently agreed to create clothing designed by students at the Fashion Institute of Technology, for example.

“Getting the right fit isn’t a size issue; it’s an inventory issue,” Kirby Best, OnPoint chairman, told Retail Dive. “Someone can order exactly what they want, and we can make it for them.”

3D Printing Is a Technology for Retail’s Future

Baytar, whose research at Cornell focuses on 3D modeling, prototyping and body scanning as it applies to the making of clothing, says that the state of 3D printing is not developed enough yet to work for mass production.

“We’ve been seeing some examples of using 3D printing for catwalks,” she says.

Artist and designer Iris van Herpen, for example, created 3D-printed “face jewelry,” shown during this year’s Paris Fashion Week; she’s also created one-off dresses for Beyoncé, Björk and Lady Gaga. And snowboarder Amy Purdy wore a 3D-printed dress for her dance performance in the 2016 Paralympics Opening Ceremony.

The process may be more practical for prototypes than products at this point. For example, while adidas used 3D printing to make concept shoes out of recycled ocean waste, the resulting limited-edition models were not made the same way.

“This part of the process seems to have been dropped for mass production,” reported The Verge.

In the long run, Baytar says, 3D printing could benefit clothing makers: “Manufacturing doesn’t need to be completed in another country — more could be done in the U.S. — and this is going to bring products quicker to market.”

As for 3D printing of mass-market garments, she says, “I believe that it may happen in the future. It’s a matter of finding the perfect materials and the perfect way of 3D printing with those materials.”