How 3D Printing Can Power Renewable Energy

The energy industry is in a state of transition, shifting to more renewable and sustainable sources of power as global concern over climate change rises. One of the biggest challenges of this transformation is producing the equipment needed to harness resources such as wind and solar energy and turn them into power for homes and businesses.

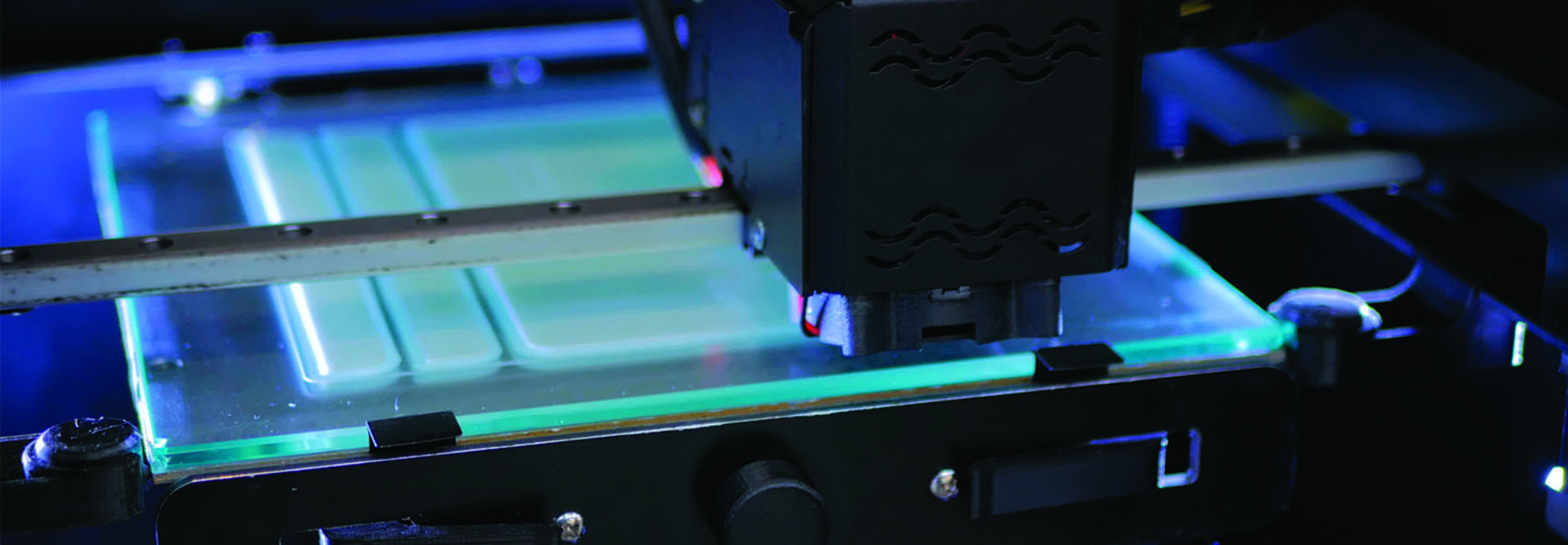

3D printing can play an important role in keeping costs in line. Printing solar panels can cut manufacturing costs in half, according to Future Power Technology. In addition to production savings, MIT researchers claim the printed panels could be up to 20 percent more efficient than traditional panels. 3D printed panels are much thinner than traditional ones, allowing them to be easily transported without damage.

Wind energy also stands to gain from 3D printing. The Department of Energy’s Wind Energy Technologies and Advanced Manufacturing offices have already partnered with public and private organizations to spearhead the 3D printing of turbine blade molds. Manufacturing blades is a labor-intensive process, done mostly by hand. But being able to make the molds faster and more efficiently can go a long way to contain those costs. It also helps curb transportation burdens, as sending a printer to a job site is much easier than sending a 50-foot mold.

Utilities Can Keep Older Machines in Working Order

As anyone who has ever owned an old car or appliance knows, at some point, the manufacturer stops making parts for outdated models. While equipment should be updated to make sure the latest technology is being utilized, it can be frustrating for utilities to have to replace an entire piece of heavy machinery merely because one single part can’t be fixed.

A 3D printer can make parts that have been discontinued, allowing expensive pieces of equipment to remain active safely. Future Power Technology reports that, in addition to replacing broken parts, 3D printing could also enable companies to make parts that are unique to their needs and goals.

This could help each field of wind turbines or solar panels operate at peak efficiency. Siemens Energy Sector made the first 3D printed metal replacement parts for an industrial gas turbine in 2018, noting that the milestone shortened the lead time on traditional production of the part by 40 percent.

MORE FROM BIZTECH: Read how utilities are using AI to improve their use of renewable energy.

Never Run Out of Needed Tools with 3D Printing

It’s not only parts that could be 3D printed to save costs — everyday tools that utilities burn through quickly can be printed as well. Multiple research groups are looking at ways to print batteries, which many manufacturers need in large supply to power tools, equipment and everyday office supplies.

For example, Manchester Metropolitan University is developing a 3D-printed battery from graphite that could potentially last longer than traditional lithium-ion batteries. Harvard University researchers are is working on a printed miniature lithium-ion battery, while IBM and ETH Zurich have 3D-printed the first liquid battery (which could produce power while it cools, potentially eliminating the dangers of overheating).

Being able to make batteries of any size and any power, with specific kinds of materials, could prove crucial for the future of the industry. The flexibility it provides, along with increased efficiency and costs containment, could end up being a game changer.