How 3D Printing Helps Businesses Beat the Competition

3D printing makes headlines when someone uses it to make a functional car or a working handgun, but does the technology have a place in today’s small and medium-sized business landscape? Some high-end systems still cost over $1 million, but times are changing: Desktop 3D printer models from companies such as Afinia, 3D Systems and MakerBot can now be had for little more than $1,000, making them affordable for almost everyone.

Prototyping tops the list of use cases among SMBs, for everything from architecture and artwork to fashion accessories and gadgets. 3D printing allows for the creation of intricate designs that would be difficult to achieve using conventional techniques, and it lets designers get tactile feedback on the form and function of their visions before committing to larger-scale production.

The global 3D printing market’s value in 2018, up 48 percent from 2013

SOURCE: Canalys, March 2014

Eroding Cost Barriers

In the past, prototypes of this sort would need to be sent out to 3D printing manufacturers at great expense and would take days or weeks for just an initial sample. For cost reasons, output based on lower- quality plastic filament or photopolymers remains preferable to metals, and even plastics can be remarkably useful for field testing ideas.

But 3D printing offers SMBs more than just prototyping.

“Rapid growth is currently occurring in industries that use injection-molded products,” says Cathy Lewis, chief marketing officer of 3D Systems. “Instead of paying hundreds of thousands of dollars to set up production, with 3D printing you can simply produce end-use parts on demand at just a cost per part.”

Lewis notes that SMBs often take their ideas from prototyping to small-scale production on affordably priced printer models. Then, when demand merits global distribution, they can outsource production to a full digital manufacturer, such as 3D Systems’ own Quickparts. In this way, SMBs can expand their reach from local to global in months rather than years.

As promising as 3D printing is, however, it still faces some obstacles.

“A traditional IT manager may have some experience with computer-aided design programs, but is unlikely to also have the engineering and design skills required for any complex objects and prints,” says Joe Kempton, research analyst with Canalys.

SMBs without such in-house expertise, he suggests, should send their designs to third-party 3D print shops, which are more likely to have not only the skills, but also larger and more advanced printers.

Not Too Long to Wait

That’s today. For the future, all bets are that 3D printing will become commonplace. It took two decades for inkjet printers to drop in price from $1,000 to practically free; 3D printing seems likely to follow a similar course. And as the range of printable materials expands, so too will the technology’s use among SMBs, particularly in sectors such as food, health and education.

“Big players such as Autodesk, Amazon and HP will increasingly move into the market,” Kempton says, “and they will turn their attention to more underdeveloped areas — with SMBs high on their list of targets.”

Ideas That Inspire

The explosion of 3D-printed final products (many funded through Kickstarter and other crowdfunding sites) has driven interest in the technology as a viable tool for small and medium-sized businesses. Cathy Lewis of 3D Systems points to some winning examples:

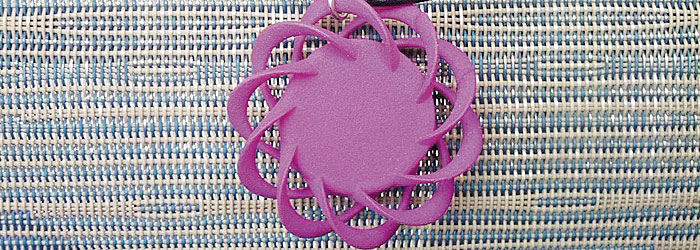

UpLocket, a nylon pendant that lets the wearer share photos via near-field communication.

Pi-Top, a do-it-yourself kit for building a notebook.